Fluid-Structure Interactions and Noise Control Lab

Self-excited acoustic resonance in axisymmetric shallow cavities and Two-phase fluid-structure interaction in a steam generator

About

At the Fluid-Structure Interaction and Noise Control (FSNC) lab, we perform fundamental and applied research in aeroacoustics, flow-sound interaction, fluid–structure interaction, vibration and structural dynamics, noise and vibration control, structural integrity, and wear analysis, aiding the development and operation of automotive, aerospace, and energy systems. Our objective is to develop innovative techniques that can be used to alleviate and control the occurrence of acute noise problems and/or excessive vibrations in real-life industrial applications to improve efficiency and reduce their susceptibility to fatigue failures.

Research

- Aeroacoustics and Flow-Sound Interaction

- Fluid-Structure Interaction

- Structural Dynamics and Integrity

- Noise and Vibration Control

- Experimental Facilities

Aeroacoustics and Flow-Sound Interaction

Free shear flows, such as wakes behind bluff bodies, free shear layers over cavities and side branches, and jet flows through orifices and valves, are highly unstable. The instabilities of the free shear flows generate periodic vorticity shedding with frequencies that vary linearly with the flow velocity. In turbulent flow, which is typical in many industrial applications, the vorticity shedding is weak and highly unorganized/incoherent. However, when the vorticity shedding couples with an acoustic mode a feedback mechanism occurs and the vorticity shedding becomes stronger and much more coherent. This often leads to the generation of excessive vibrations and/or acute noise problems. Therefore, a deep understanding of the flow-sound interaction mechanisms and the resulting energy transfer between the flow and sound fields is necessary in order to develop reliable guidelines that can be used to predict and avoid their occurrence.

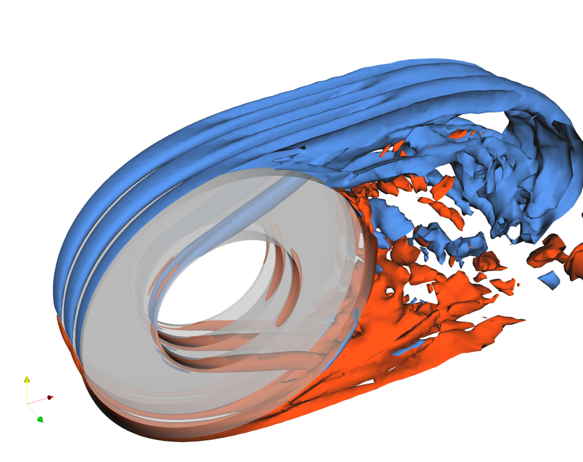

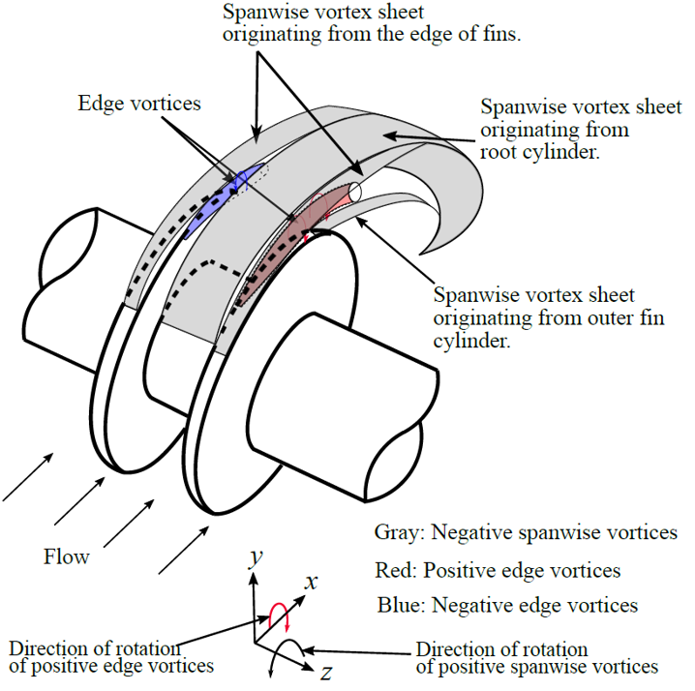

Effect of fins on the flow-structure from a circular cylinder

Islam & Mohany, Physics of Fluids, (2020)

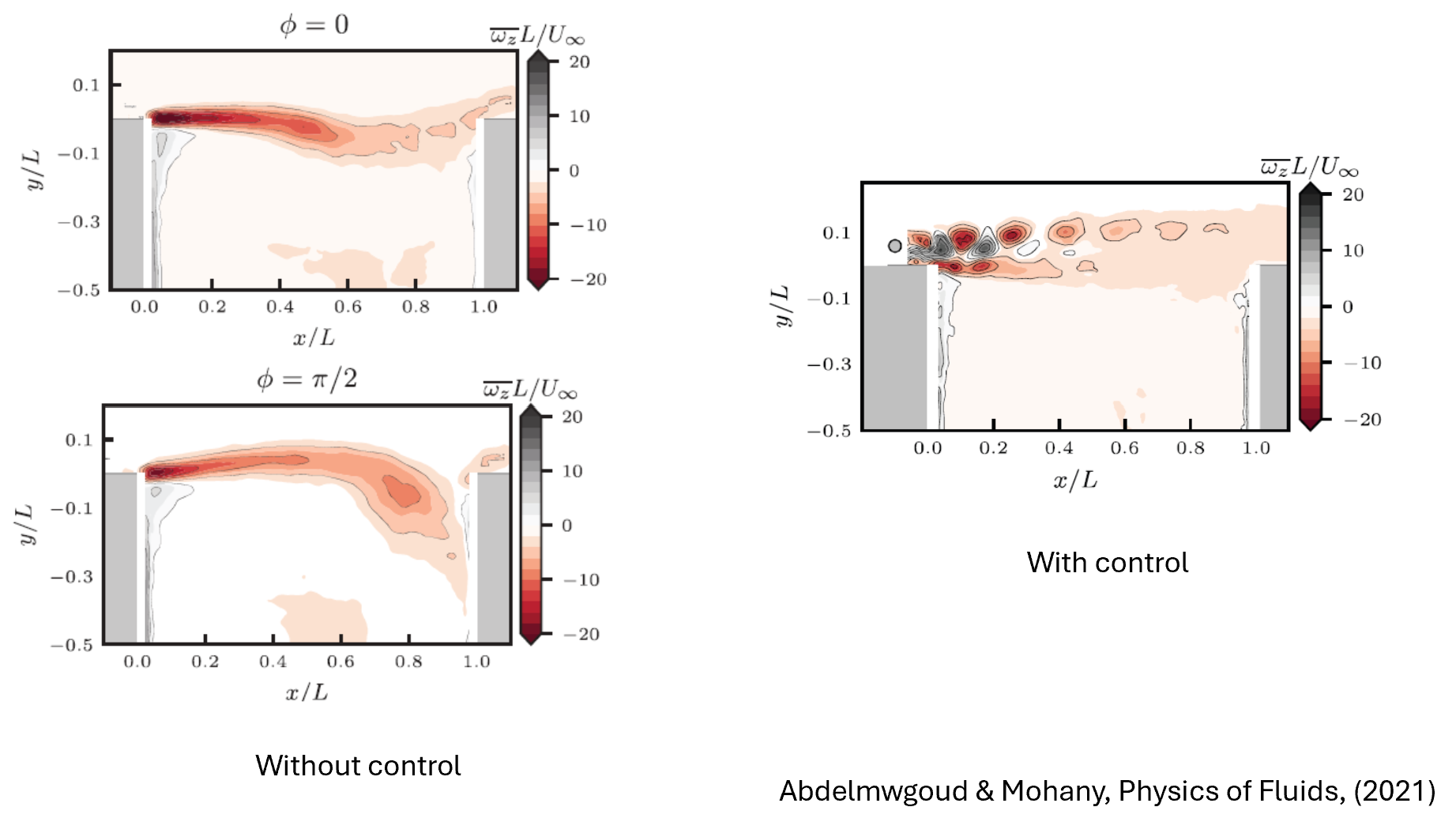

Suppression of self-sustained shear layer oscillations over cavities

Self-excited acoustic resonance in axisymmetric shallow cavities

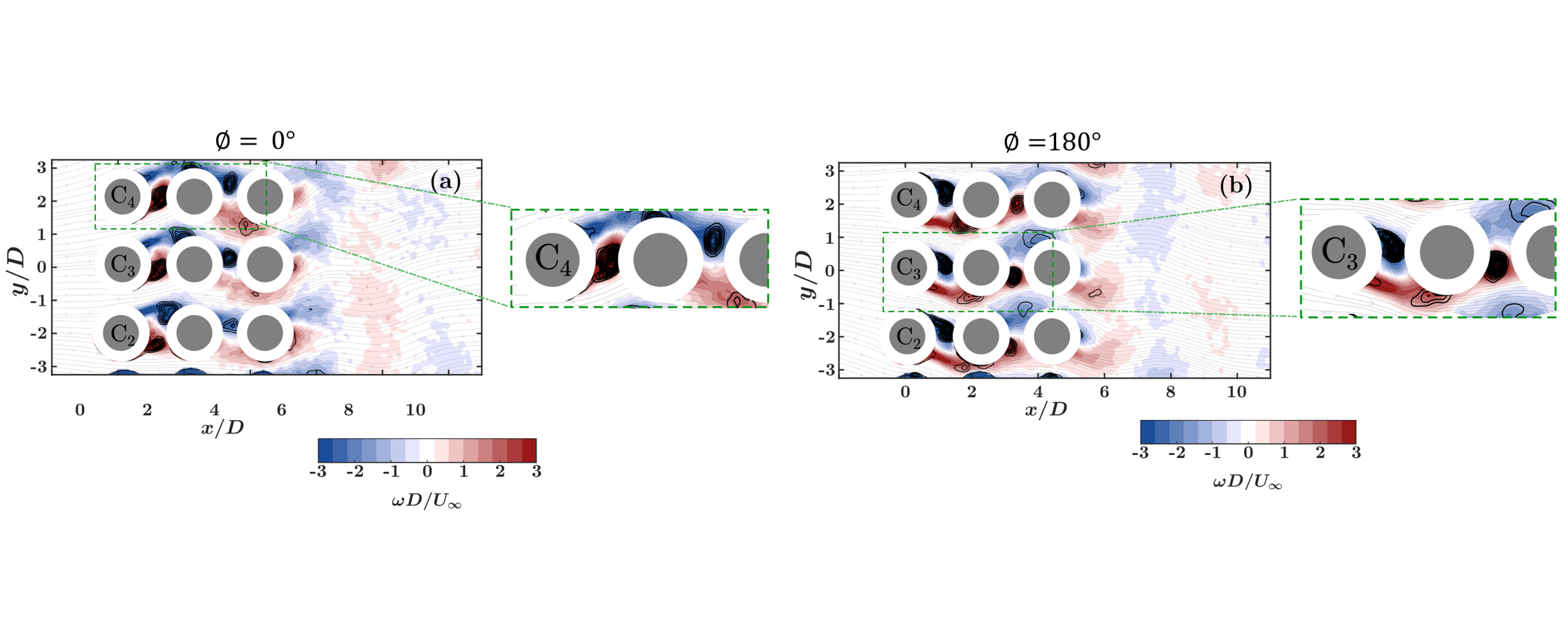

Strouhal periodicities and flow-excited acoustic resonance in tube arrays

Fluid-Structure Interaction

Fluid flow in various industrial components, such as valves, pipes, pumps, heat exchangers, and steam generators, can give rise to undesired fluid-structure interactions. Fluid–structure interaction is the coupled phenomenon in which a fluid flow and a deformable or moving structure mutually influence each other through exchanged forces and displacements. Inadequately designed systems may result in excessive vibrations leading to their premature failure. Thorough analysis of this interaction sets safe operational boundaries for equipment and facilitates the development of more efficient designs that adhere to contemporary standards.

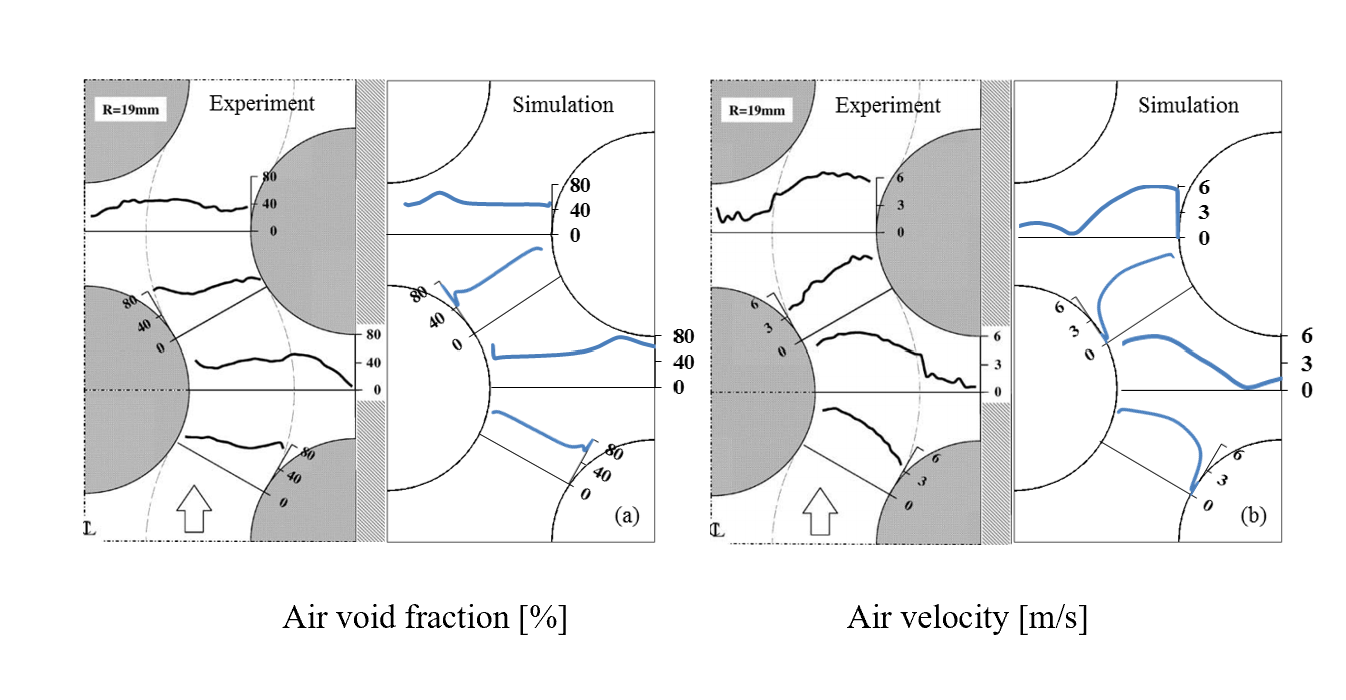

Two-phase fluid-structure interaction in a steam generator

Sadek, Mohany & Hassan, JFS (2018, 2020, 2021)

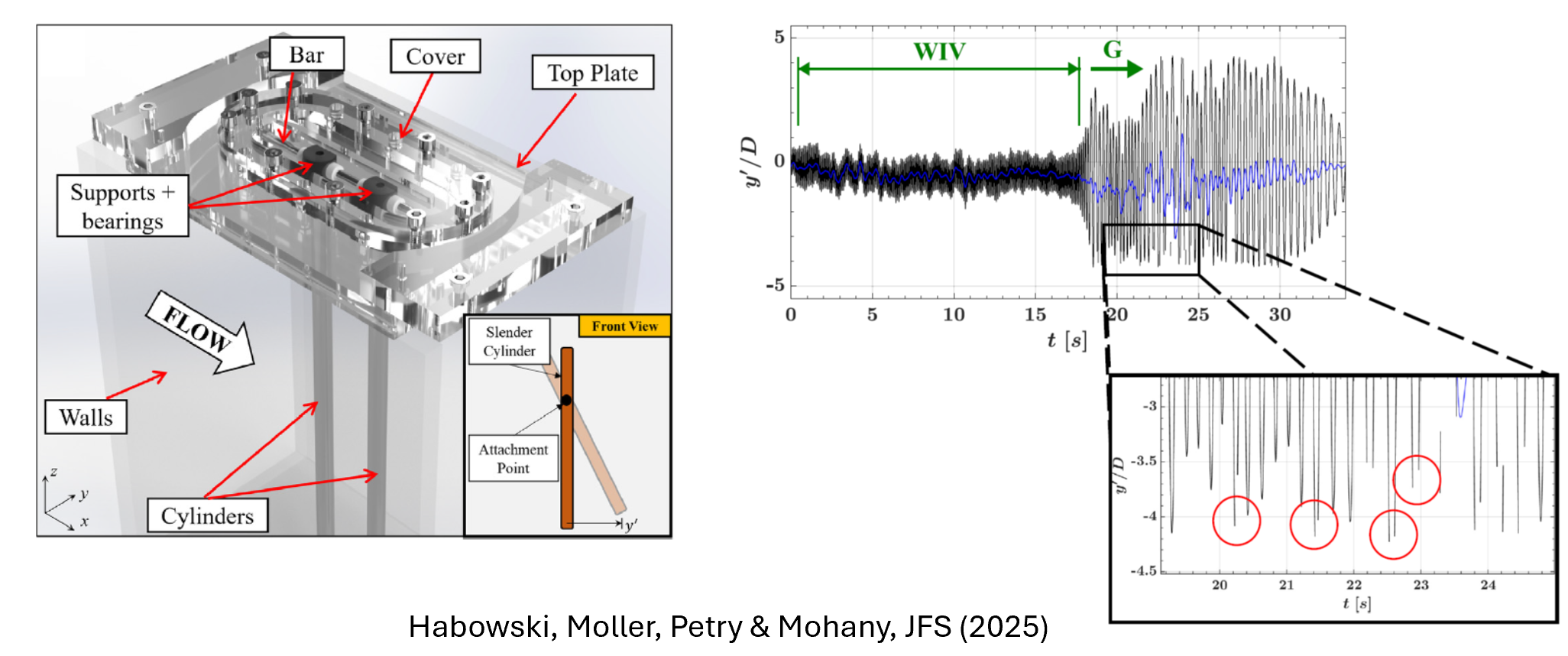

Flow-Induced Vibration Characteristics of Pendulum Cylinders for Offshore Wind Turbine Applications

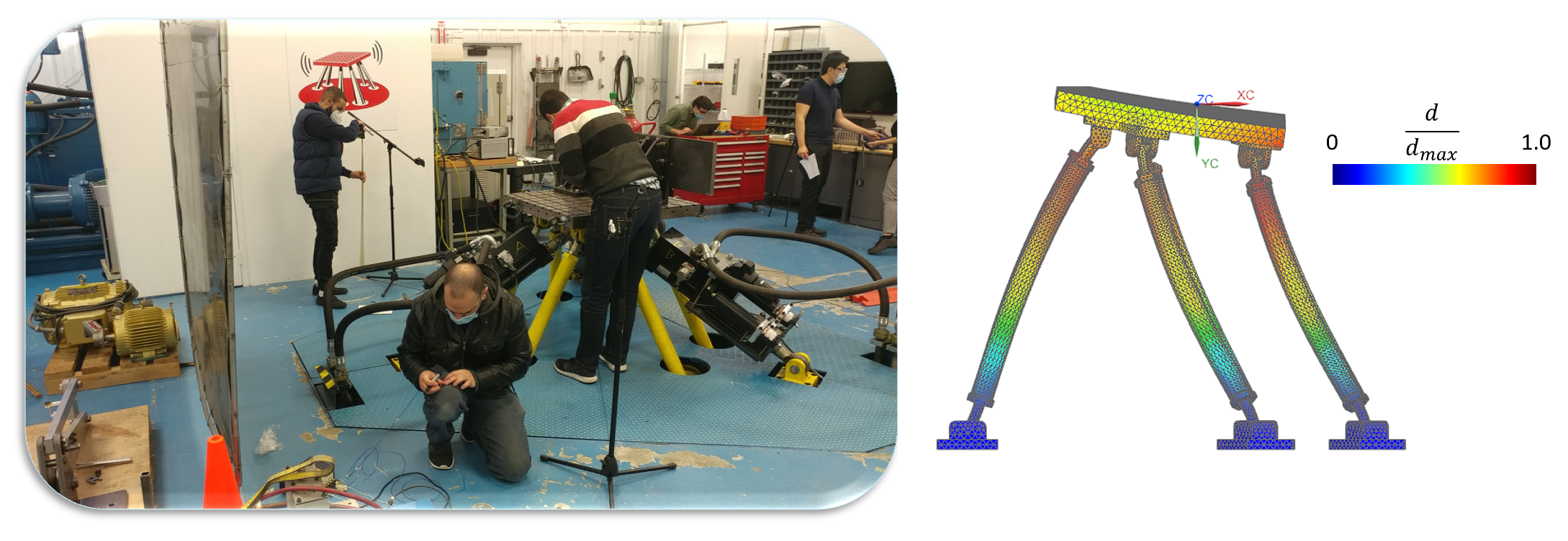

Structural Dynamics and Integrity

Industrial components are constantly subjected to dynamic loads and vibrations, whether these arise during normal operation, as in wind turbines and rotating machinery, or from unexpected events such as earthquakes and impact loads. Understanding and predicting how a structure responds to these forces lies at the heart of structural dynamics, which examines how motion, stiffness, damping, and inertia shape the way a system vibrates over time. These dynamic responses directly affect structural integrity, since repeated or excessive vibrations can lead to fatigue, crack initiation, and ultimately premature failure. By accurately modeling system behavior under both operational and accidental conditions, engineers can reduce harmful vibrations, extend service life, and ensure that structures remain safe, reliable, and suitable for long-term use. At the FSNC Lab, we conduct both experimental and numerical studies to evaluate the structural dynamics and integrity of a wide range of components across various industries.

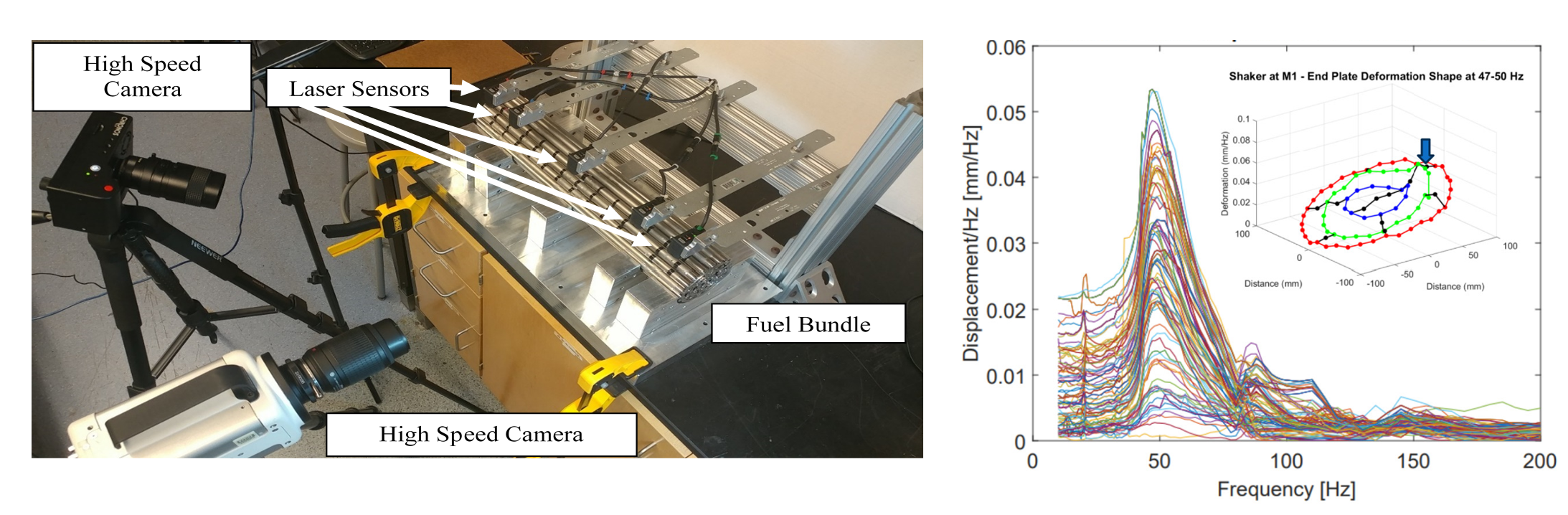

Dynamic characteristics of nuclear fuel bundles

Troubleshooting and Performance Assessment of a Seismic Testing Table

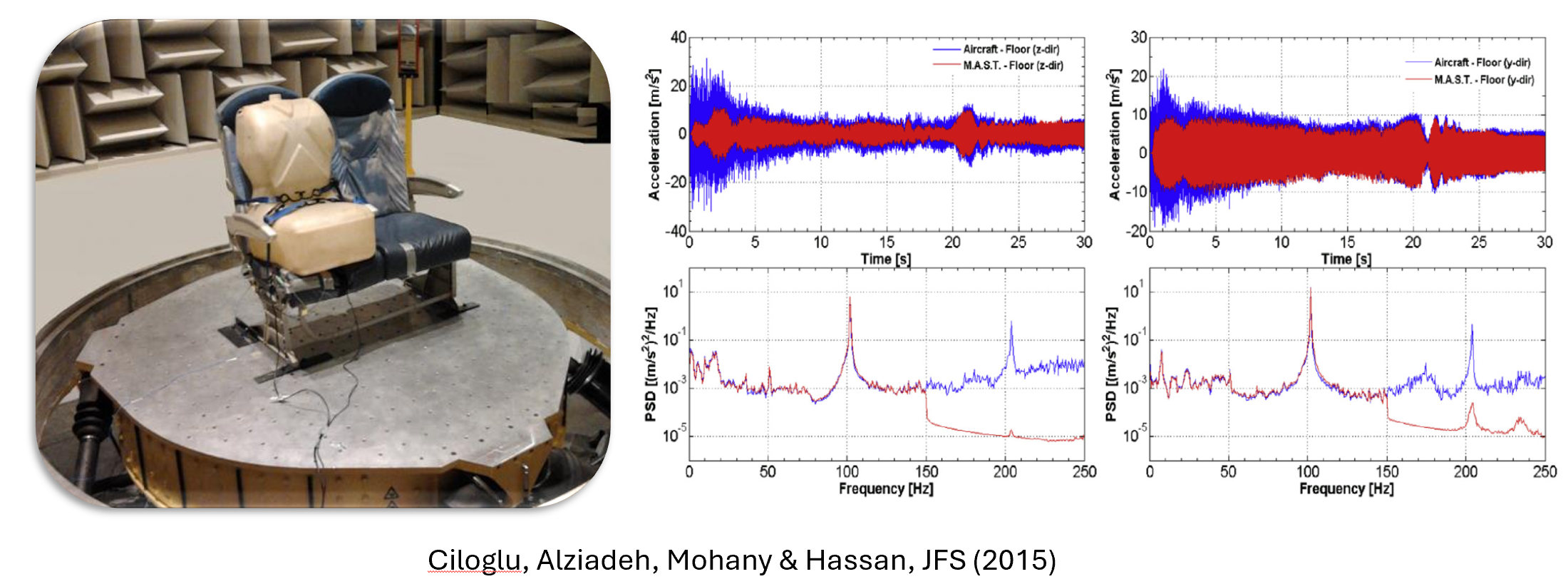

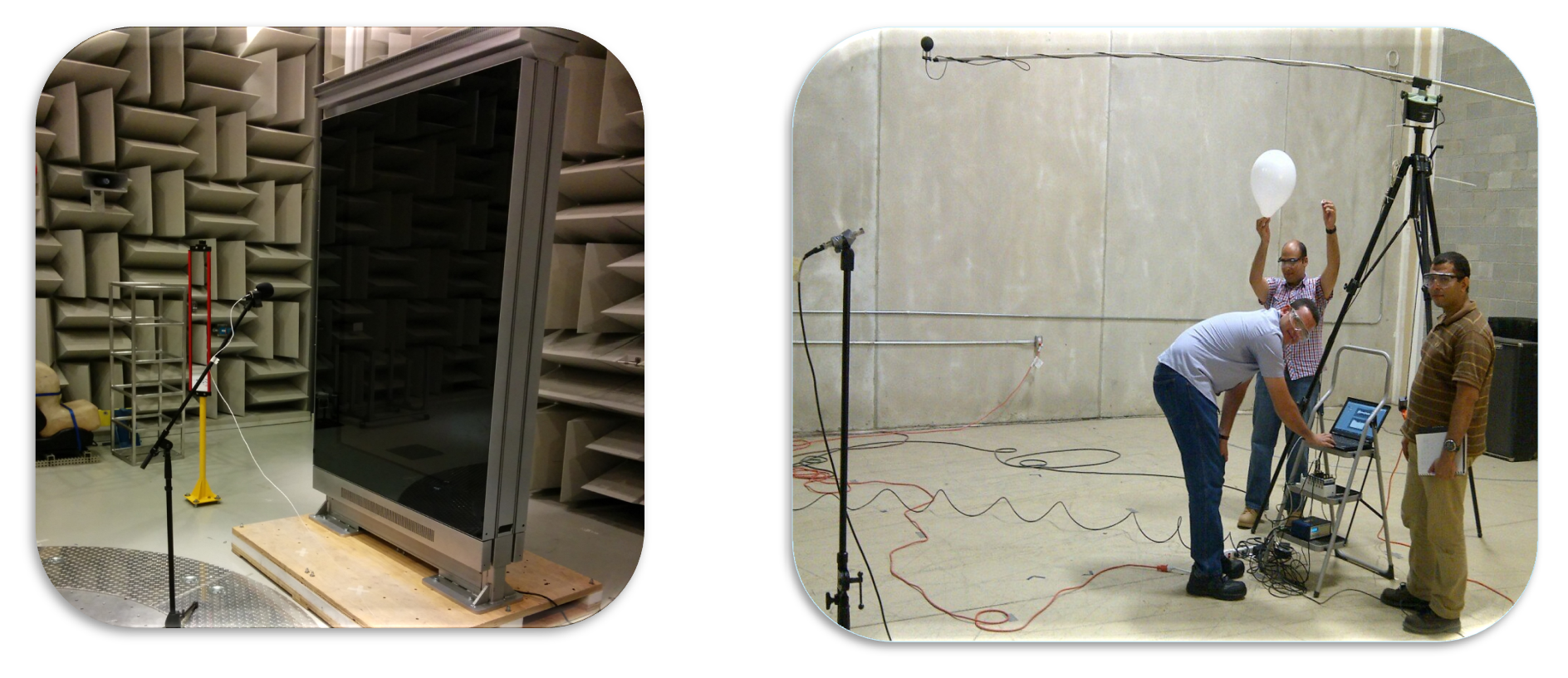

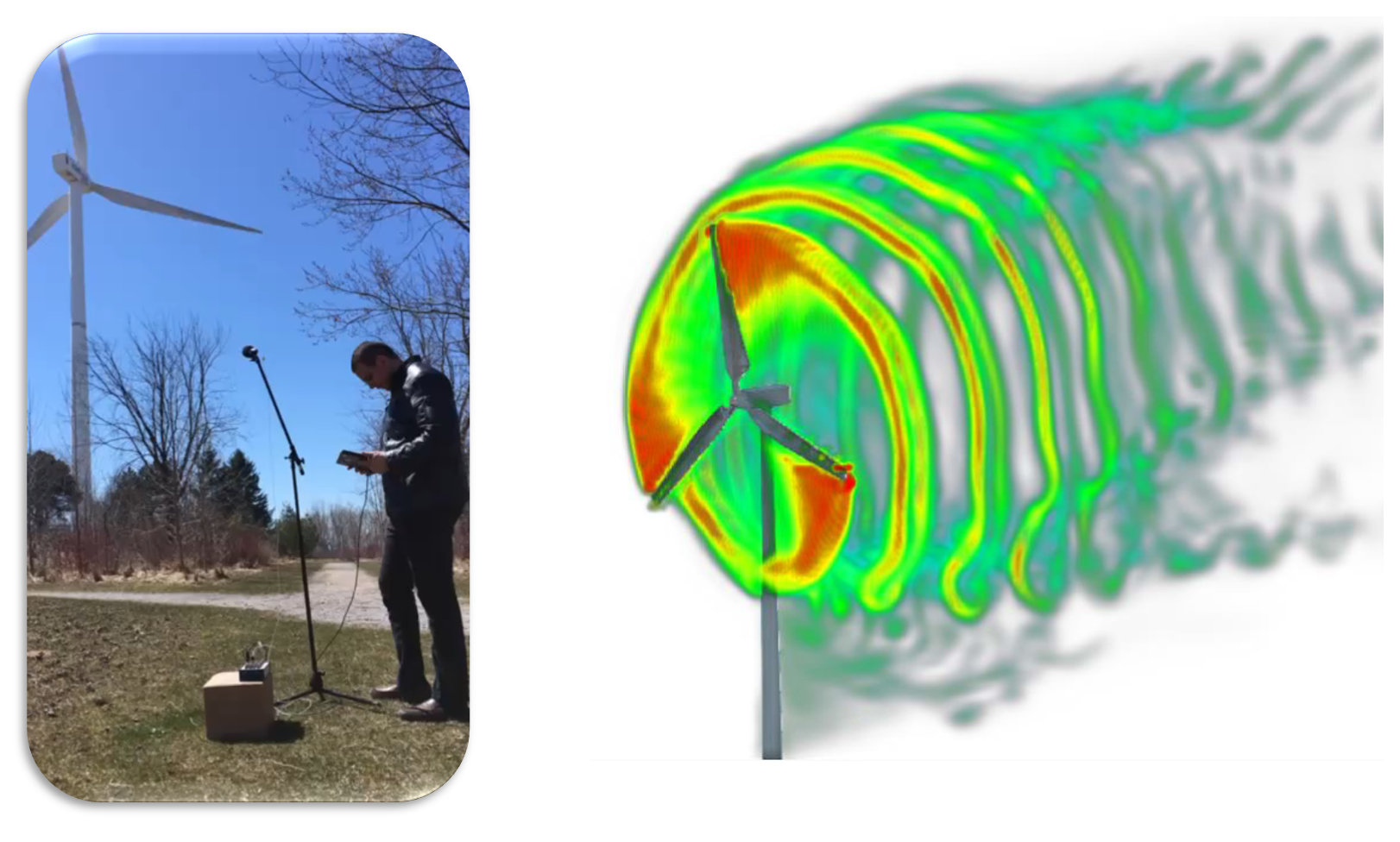

Noise and Vibration Control

Our research group has a strong track record of developing innovative, efficient, and cost-effective strategies for controlling noise and vibration across a wide range of industrial applications. Through a combination of fundamental research and practical engineering, we design solutions that not only reduce unwanted sound and vibrations, but also improve performance, reliability, and user comfort.

Assessment of the whole body vibration exposure and the dynamic seat comfort in passenger aircraft

Noise reduction and acoustic testing of digital display units and a commercial reverberation chamber

Field Testing and Simulation of Flow Structures and Noise in Wind Turbines

Dr. Atef Mohany

Dr. Atef Mohany

BSc, MSc, Ph.D., P.Eng, FASME, FCSME

Assistant Dean, Graduate Studies and Professor

Dr. Mohany is a Professor in the Department of Mechanical and Manufacturing Engineering at Ontario Tech University. He is also the Founding Director of the Aerodynamics and Climatic Adaptation Research Center and a former University Excellence Research Chair in Structural Integrity. Over the years, Dr. Mohany has held several administrative roles, including Chair of the Mechanical and Manufacturing Engineering Department and Founding Graduate Program Director. Currently, he serves as the Assistant Dean of Graduate Studies in the Faculty of Engineering and Applied Science. Dr. Mohany started his academic career as an Assistant Professor in the Department of Mechanical Engineering at the University of New Brunswick in 2010, and then in January 2012, he joined Ontario Tech University and established a leading-edge research group in aeroacoustics, fluid-structure interaction, flow-induced vibration, structural integrity, and noise & vibration control. The majority of his research projects address a wide range of practical engineering problems related to the design and operation of automotive, aerospace, and energy systems. Prior to moving into academia, he was a Nuclear R&D Engineer at Atomic Energy of Canada Limited (AECL), Chalk River Laboratories. During his tenure at AECL, Dr. Mohany was involved in several strategic projects related to the design of key components in the advanced CANDU reactor as well as the operation of nuclear power plants in Canada and around the world. Dr. Mohany earned his Ph.D. from McMaster University, Canada, in 2006. He has received numerous distinctions and merit awards, including the University Research Excellence Award (2025), the Faculty of Engineering and Applied Science Research Excellence Award (2024), the University Student Choice Award for Excellence in Teaching (2024), and the Outstanding Service Award from ASME (American Society of Mechanical Engineers) for significant contributions to the FSI Technical Committee (2023. Together with his research group, he has a US patent and over 180 publications in reputable journals and conferences. He has supervised and co-supervised 17 PhD students, 19 MASc students, 6 Post-Doctoral Fellows, and 26 research assistants. Dr. Mohany is a Professional Engineer in Ontario and a Fellow of both the American Society of Mechanical Engineers (ASME) and the Canadian Society for Mechanical Engineering (CSME). He currently serves as the Chair of the ASME Fluid-Structure Interaction technical committee and Associate Editor for the ASME Journal of Pressure Vessel Technology. Additionally, he is a member of the National Standard Committee ISO/TC 11 on Boilers and Pressure Vessels, and the National Standard Committee ISO/TC 43 on Acoustics, including its subcommittee ISO/TC 43/SC1 on Noise.

Post-Doctoral Fellow

1. Rasha Noufal

PHD Students

1. Ali Saudy

2. Amin Nasrollah

Masters Students

1. Kogul Satkunanantharajakumar

2. Tufan Gokpinar

Publication

- Habowski, P. B., Möller, S. V., Petry, A. P., & Mohany, A. (2025). On the oscillatory behavior of two pendulum-like tandem circular slender cylinders. Journal of Fluids and Structures, 139, 104424.

- Noufal, R., Kishawy, H., & Mohany, A. (2025). Vorticity shedding and acoustic resonance excitation in a tube array with different compactness. Physics of Fluids, 37(11).

- Shahryari, B., Mirabolghasemi, A., Eskandari, S., Chen, X., Deü, J. F., Ohayon, R., Mohany, A. & Akbarzadeh, A. (2025). Conformally Perforated Shellular Metamaterials with Tunable Thermomechanical and Acoustic Properties. Advanced Functional Materials, 2506062.

- Mohany, A., Hammad, O., Kishawy, H., Hassan, M., & Shaaban, M. (2025). Acoustic resonance excitation and source mapping in co-axial piping systems with different junction edge geometries. Journal of Sound and Vibration, 119163.

- Mohany, A., Shoukry, A., & Pastur, L. (2024). Self-selection of flow instabilities by acoustic perturbations around rectangular cylinder in cross-flow. Journal of Fluid Mechanics, 998, A51.

- Shaaban, M., Noufal, R., Alziadeh, M., & Mohany, A. (2024). Spinning dynamics of self-excited azimuthal acoustic modes in cavities. Physics of Fluids, 36(7).

- Noufal, R., Alziadeh, M., & Mohany, A. (2024). Control of vortex shedding and acoustic resonance of a circular cylinder in cross-flow. Journal of Fluids and Structures, 126, 104094.

- Hammad, O. S., & Mohany, A. (2023). Vortex shedding characteristics and hydrodynamic forces of stationary and elastically mounted side-by-side cylinders fitted with small diameter control rods. Journal of Fluids and Structures, 120, 103908.

- Alziadeh, M., & Mohany, A. (2023). Flow structure and aerodynamic forces of finned cylinders during flow-induced acoustic resonance. Journal of Fluids and Structures, 119, 103887.

- Elbanhawy, Osama, Marwan Hassan, and Atef Mohany. "Modelling of fully-flexible fuel bundles." Nuclear Engineering and Design378 (2021): 111014.

- Abdelmwgoud, M., & Mohany, A. (2021). Control of the self-sustained shear layer oscillations over rectangular cavities using high-frequency vortex generators. Physics of Fluids, 33(4).

- Islam, M. R., & Mohany, A. (2020). Vortex shedding characteristics in the wake of circular finned cylinders. Physics of Fluids, 32(4).

- Sadek, O., Mohany, A., & Hassan, M. (2020). Numerical simulation of streamwise fluidelastic instability of tube bundles subjected to two-phase cross flow. Journal of fluids and structures, 92, 102816.

- Lato, T., & Mohany, A. (2019). Passive damping of pressure pulsations in pipelines using Herschel-Quincke tubes. Journal of Sound and Vibration, 448, 160-177.

- Shaaban, M., & Mohany, A. (2018). Flow-induced vibration of three unevenly spaced in-line cylinders in cross-flow. Journal of Fluids and Structures, 76, 367-383

Partners

Group Photos