2025 ENE Capstone Projects

Department of Energy and Nuclear Engineering

-

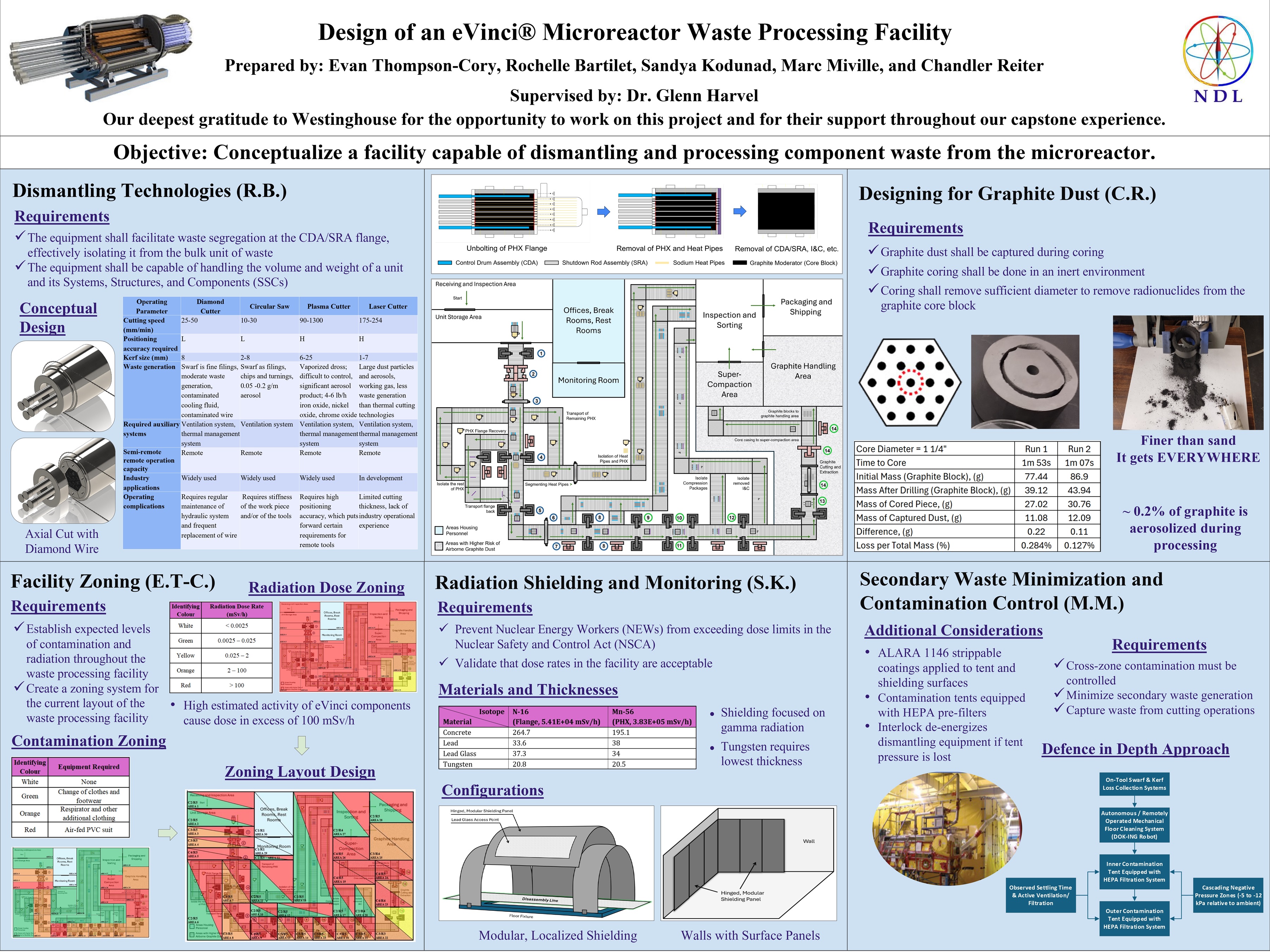

FIRST PLACE: Design of an eVinci Microreactor Waste Processing Facility

Group Members: Evan Thompson-Cory, Sandya Kodunad, Rochelle Bartilet, Chance Reiter, Marc Miville

Faculty Advisor: Dr. Glenn HarvelDescription: This project will develop the concept of a decommissioning facility that could disassemble small modular reactors at a central site. The design uses the Westinghouse eVinci reactor as a concept for the facility development. Radiation loading, dismantling, and contamination control are developed in the project.

-

SECOND PLACE: Design of a Small Test Loop for Liquid Metals

Group Members: Vanessa Greene, Thomas Lupenette, Marcel Drabick, Richard De Groot

Faculty Advisor: Dr. Matthew KayeDescription: This project included the design and construction of a liquid metal test loop apparatus, for the purpose of testing flow assisted corrosion (FAC) effects on different pipe geometries. Key elements of the project included selection of the appropriate liquid metal, selection of loop materials and construction of the loop, performing flow and stress calculations, and simulating flow through the loop prior to operation. One objective is to measure FAC effects on different types of piping geometry.

-

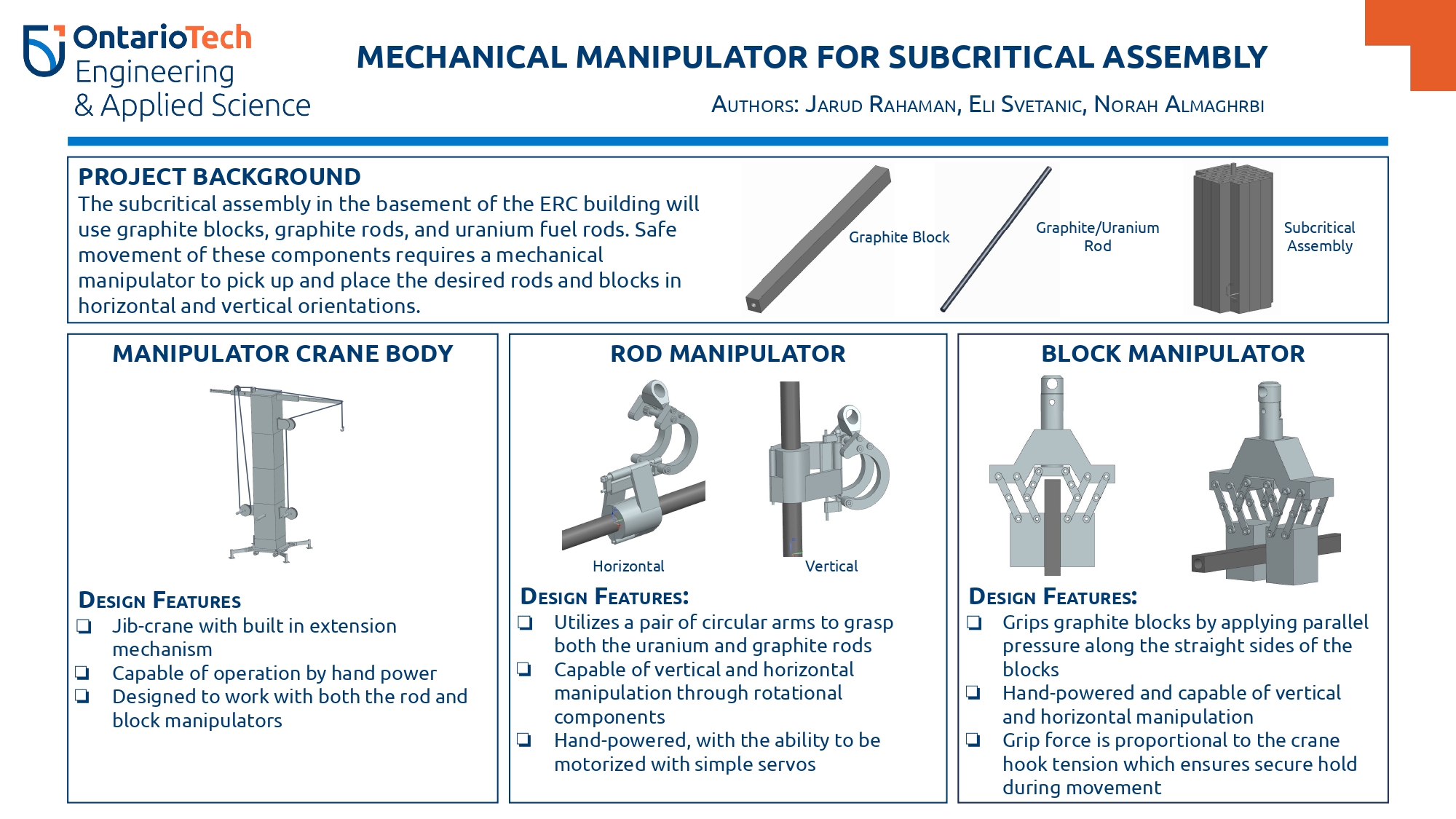

THIRD PLACE: Design of a Mechanical Manipulator for Subcritical Assembly Blocks and Fuel

Group Members: Eli Svetanic, Jarud Rahaman, Norah Almaghrbi

Faculty Advisor: Dr. Eleodor NichitaDescription: Ontario Tech is in the process of commissioning a flexible-configuration subcritical assembly which consists of graphite blocks and UO2 rods. One of the subcritical assembly’s advantages is its ability to be configured in different geometries by rearranging the graphite blocks and uranium rods. Both blocks and rods are heavy and their manipulation by a single individual presents safety risks. It is therefore desirable to design a mechanical manipulator to handle and position the graphite blocks and uranium rods in different configurations. The project’s objective is to design a mechanical manipulator for handling Ontario Tech subcritical assembly blocks.

-

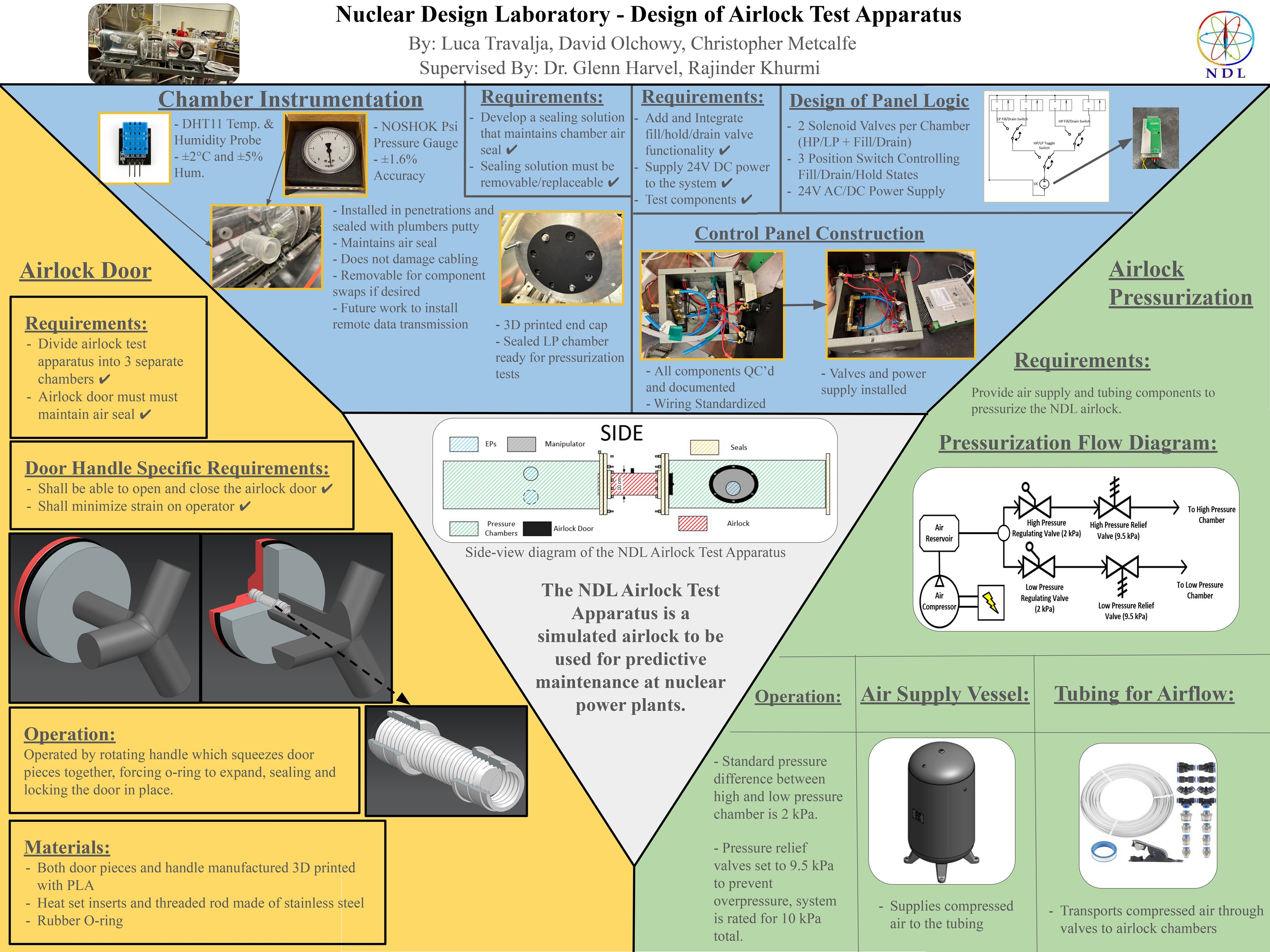

Design Upgrading and Commissioning of Airlock Test Rig

Group Members: Luca Travalja, David Olchowy, Chris Metcalfe

Faculty Advisor: Dr. Glenn HarvelDescription: This project will advance design and construction of an airlock test system. The test system will allow for the capture of experimental data to support maintenance modelling development on nuclear related systems. The project includes pressure and inventory control and airlock chamber design.

-

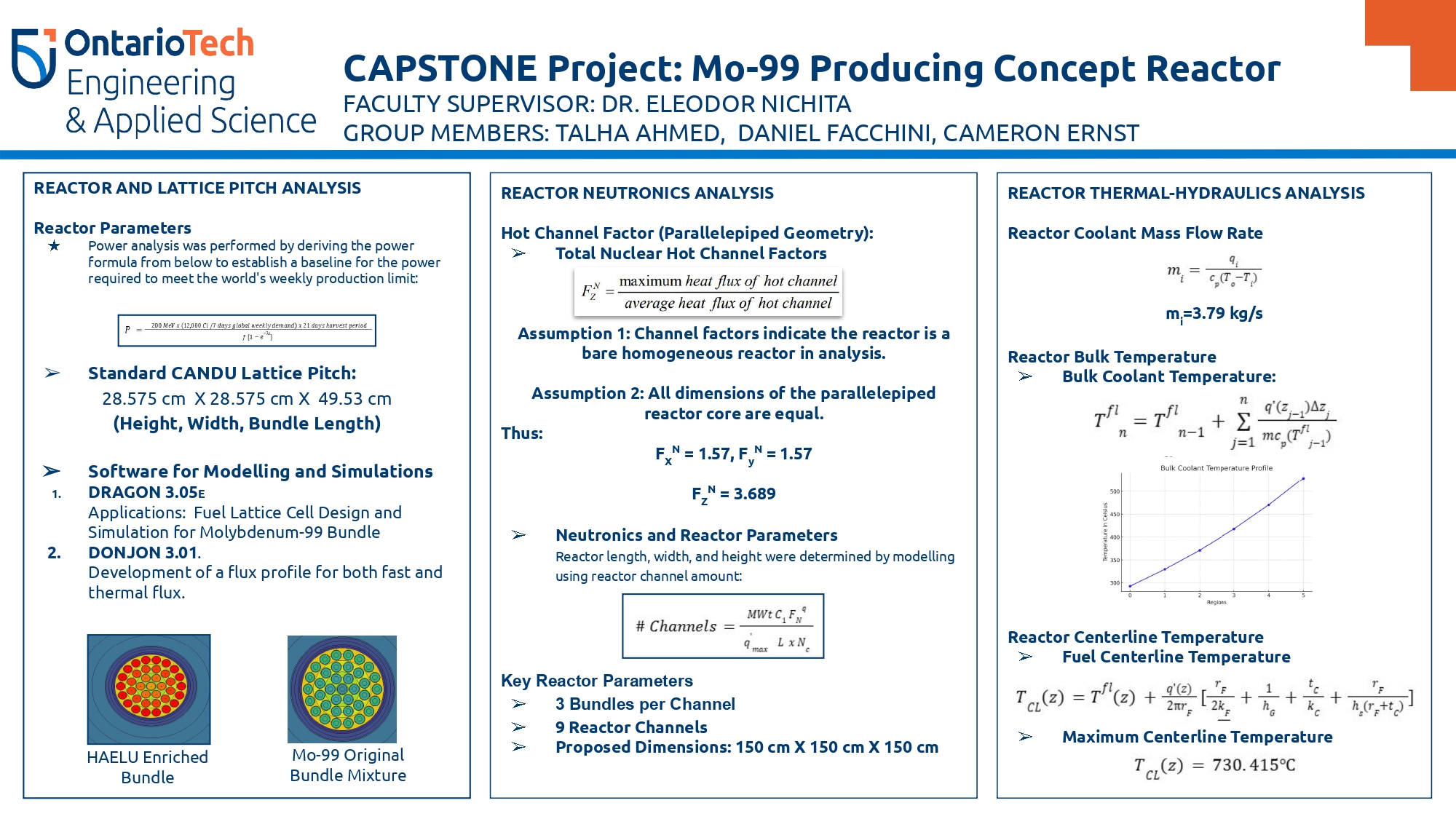

Conceptual Design of a Molybdenum-99 CANDU-type Microreactor using CANDUtype Molybdenum Producing Bun

Group Members: Daniel Facchini, Talha Ahmed, Cameron Ernst

Faculty Advisor: Dr. Eleodor NichitaDescription: CANDU reactors are refueled online and thus are a good choice for producing Mo-99, which needs to be harvested every three weeks. A CANDU-type fuel bundle capable of producing Mo-99 has already been designed and shown to be usable in power-producing CANDU reactors (https://hdl.handle.net/10155/1660). However, intermixing regular fuel bundles with Mo-producing bundles poses some complications for power-producing reactors. An alternative is to design a microreactor used solely for producing Mo-99 using the designed bundle. The project’s objective is the design of such a CANDU-type micro-reactor for the production of Mo-99.

-

Redesigned Annulus Spacer

Group Members: Keegan Baillon, Sean Cameron, Patrick Duggan

Faculty Advisor: Dr. Matthew KayeDescription: This project developed alternative annulus spacer designs for the CANada Deuterium Uranium (CANDU) reactor. Annulus spacers, also known as garter springs, are an essential component in CANDU reactors. The function of the garter spring is to prevent direct contact between the PT and CT from occurring during plant operation, however, all current designs have been found to move from their intended design location, which can have a significant impact on the structural integrity of the fuel channel and have a high associated cost to correct.