Thermal Engineering

This research program is dedicated to advancing thermal management technologies critical for electric vehicle (EV) battery and fuel cell systems, as precise thermal regulation of these systems is essential to optimize performance, extend lifespan, and ensure safety. Additionally, our research is dedicated to engineering integrated thermal solutions that can perform efficiently even in sub-zero environments with potential applications for space heating in buildings and transportation systems in cold climates. The research areas include but are not limited to the following:

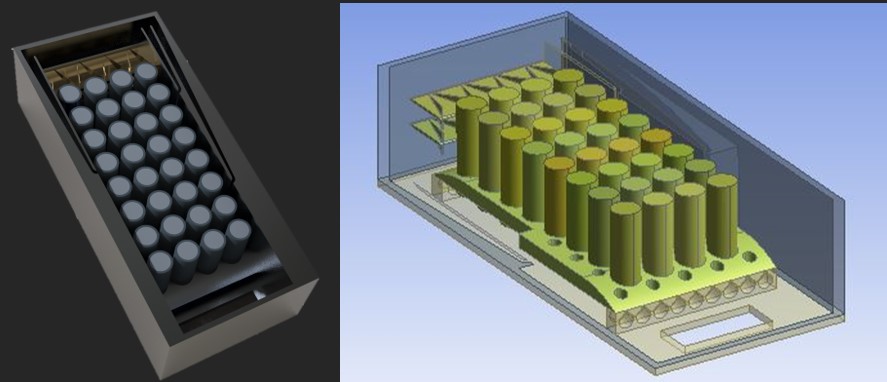

- Thermal Management of EV Battery and Charging Systems

Thermal regulation within lithium-ion batteries is pivotal for maintaining efficiency and prolonging battery life. E.g., lithium-ion batteries require uniform cooling within an optimal temperature range (25°C–40°C) to avoid thermal risks such as reduced power output, accelerated cell degradation, and potential thermal runaway at elevated temperatures. This research develops innovative, multi-modal thermal management strategies, including:- Latent Heat Water Extraction: A passive cooling system using hydrophilic channels to draw heat from batteries via capillary action, eliminating the need for mechanical pumping.

- Hybrid Cooling Systems: Integrated air, liquid, and phase change materials for robust cooling performance under variable loads.

- Shape-Stabilized Phase Change Materials (PCMs): Innovative materials designed to enhance the performance of PCMs) in thermal management applications.

- Jet Inlets and Vortex Generators: Advanced designs utilizing controlled airflow and liquid cooling to enhance heat dissipation.

- Cold-Climate Heat Pump Development

Space heating represents a large share of energy use within Canada’s building sector, where air-source heat pumps (HPs) provide a high coefficient of performance (COP) compared to electric resistance heating. However, sustaining a high COP at temperatures below -20°C is challenging. The research team works on advanced HP designs to ensure reliable, energy-efficient performance in extreme cold. - Thermal Management of Fuel Cells

Effective thermal control is critical for maximizing fuel cell efficiency, output, and lifespan. Fuel cells produce substantial heat during operation, and maintaining stable temperature ranges is vital to prevent degradation, enhance power generation, and mitigate thermal stresses. This research is focused on developing cutting-edge thermal management approaches for fuel cells, which include:- Hybrid Cooling Techniques: Integrating air and liquid cooling to optimize heat removal across diverse operating conditions.

- Phase Change Materials (PCMs): Utilizing PCMs to absorb peak thermal loads, preventing temperature spikes and thermal runaway.

- Innovative Heat Exchanger Designs: Custom-designed heat exchangers are employed to improve heat dissipation and maintain consistent temperature profiles.

Through both experimental and numerical methodologies, this research seeks scalable, energy-efficient solutions to optimize thermal performance across battery packs, heat pumps, and fuel cells, supporting advancements in sustainable technologies.